- Resurface cylinder walls so new rings will seat

- Eliminate minor cylinder wall imperfections

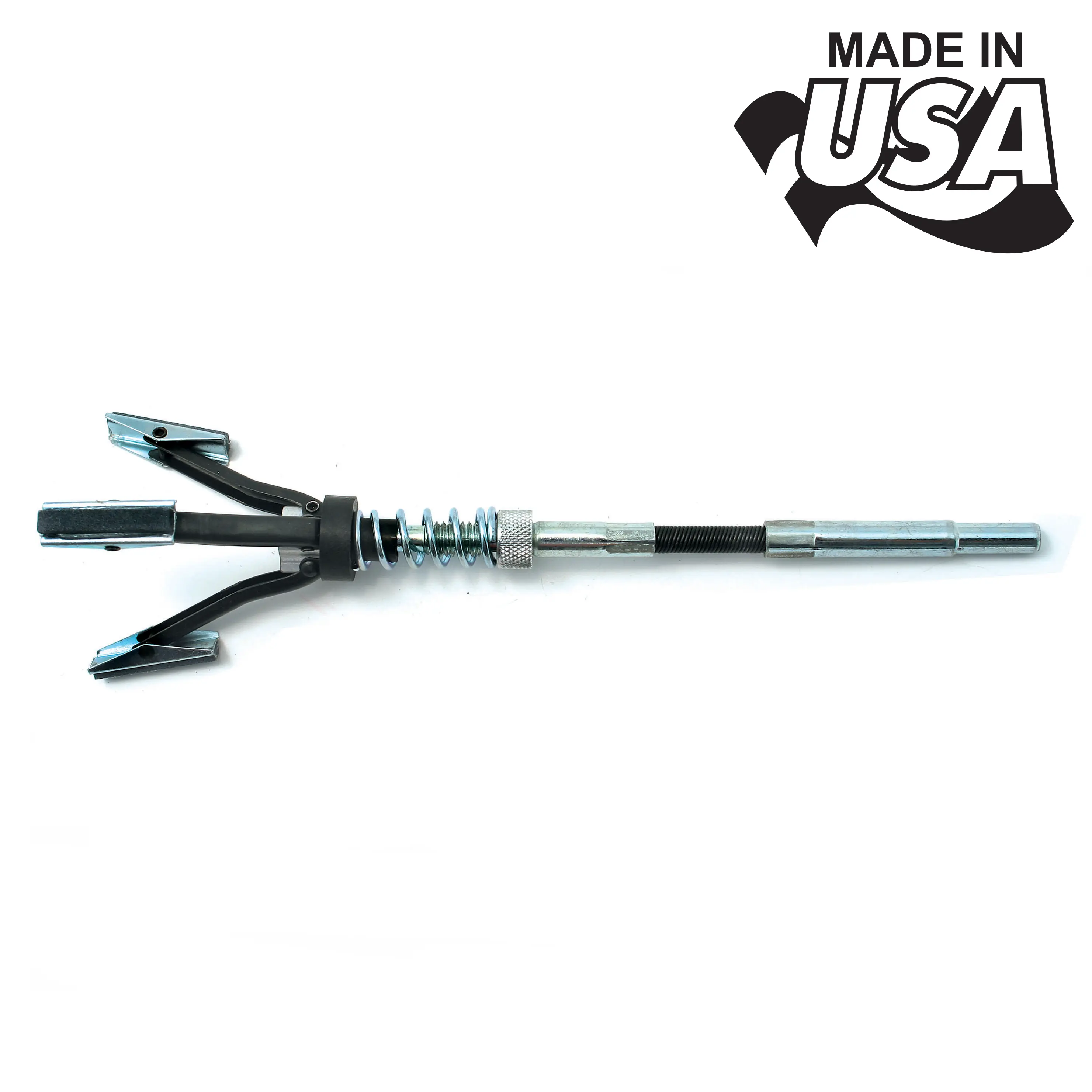

- Adjustable diameter and tension settings

- Flex shaft will fit variable speed drill

- Medium grit (220) stones

- Range: 51 – 178mm

- Stone Length: 4″ / 102mm

- Made in USA

Instructions

- Insert hone shaft into drill chuck, and tighten chuck.

NOTE: Bore may be honed dry or with light oil, but oil is generally recommended. Aerosol-type multi-purpose oil works well.

- Compress stones so they fit into cylinder, then release.

- Run drill at slow speed while moving hone in and out of cylinder rapidly. The combustion of drill rpm and stroke speed should be such that honing pattern is a 45 degree angle to bore.

CAUTION: Do not push hone so deeply into cylinder that it hits the crankshaft or main bearing webs. Also, do not draw it out or bore past the stones’ pivot point or stones will be damaged.

- Honing is completed when bore finish is even.

- Clean bore thoroughly. Use hot water and detergent or motor oil on clean rags. Do not use kerosene or other thin solvents as they will cause the abrasive particles to penetrate into the iron which will accelerate ring wear.